About Us

How Kitchen Knives Are Made

(Name engraving - Eliminating warping)

Name engraving

Because the material is too stiff to engrave any marks, the knife is heated (600-650 degrees) to engrave a name.

Because engraving must be carried out promptly when the knife is still hot and red, and because no mistakes are allowed, this is one of the most nerve-wracking processes.

Annealing

"Annealing" is carried out to equalize unevenness of the organization caused by the heat at the time of fairing. The "annealing" is completed when the knife is heated to 750-800 degrees and cooled down slowly.

Heat treatment

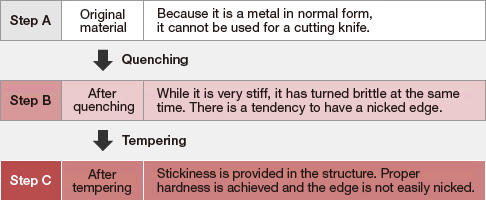

The process of quenching and tempering is generally called "heat treatment." This process determines the hardness (degree of hardness) and toughness of steel and is the most important process among all the processes requiring skills, experience, and techniques. It is very difficult to take the measure of the steel that we use in the heat treatment, and all the work is carried out by our craftsman's eyes and intuitions.

At our studio, we are particular about using "pine charcoal" when quenching, similarly to the case of Japanese swords, instead of cokes or oil. (Although pine charcoal is expensive, it is essential to create better quality kitchen knife.)

Mud coating

The front and back of the knife are coated with special mud and the knife is left to be dried. This mud is the guideline to prevent uneven burning, when determining the subtle temperature control by the "fire color of steel (burning color)."

Tempering

Even for metals, if metals are simply stiff, they turn brittle. "Tempering" is a process to provide "toughness" to steels by soaking the knife in the hot oil at 180 °C for 45 minutes.

Eliminating warping

Metals "expand" or "shrink" when heated or cooled. Because the knife tends to warp when treated with heat such as quenching and tempering, hammer by hand under normal temperature to correct the warp gradually.